What's advantages of Centralized Feeding Systems for a new plastic injection molding workshop?

Implementing a Centralized Feeding System in a new plastic injection workshop provides numerous advantages that streamline operations, enhance productivity, and ensure long-term cost efficiency. Here are the key benefits:

1. Improved Operational Efficiency

Automated Material Supply: Centralized feeding systems continuously and automatically supply raw materials to injection machines, eliminating manual handling and ensuring uninterrupted production.

Reduced Downtime: Material handling errors, like hopper shortages or overfilling, are minimized, leading to smoother operations.

2. Enhanced Product Quality

Consistent Material Supply: Uniform feeding prevents under or over-supply issues, maintaining product consistency and quality.

Moisture Control: Integrated material drying ensures resin is at the optimal moisture level, avoiding defects like bubbles or weak points in the final product.

3. Cost Savings

Reduced Labor Costs: Automation eliminates the need for manual material transportation and loading.

Energy Efficiency: Modern systems optimize energy usage, operating only when necessary, lowering energy consumption.

Waste Reduction: Precise material handling minimizes material spillage and waste.

4. Flexibility and Scalability

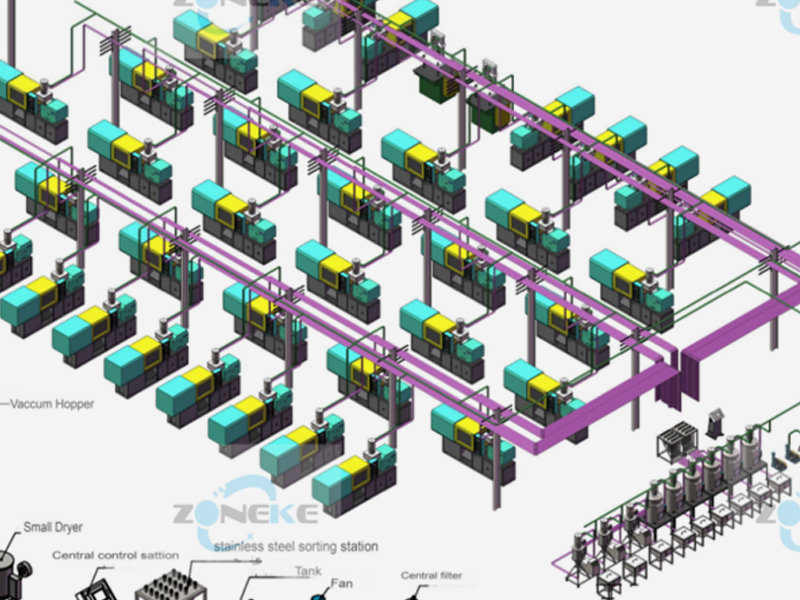

Supports Multiple Machines: One system can feed multiple injection molding machines, which is ideal for workshops with varying production needs.

Future Expansion: Modular designs allow the system to expand as the workshop grows, accommodating additional machines or materials.

5. Clean and Organized Workspace

Elimination of Material Clutter: Central silos or hoppers feed directly to machines through enclosed systems, reducing storage requirements at individual machines.

Dust-Free Environment: Closed-loop conveying prevents dust or material particles from contaminating the workspace.

6. Real-Time Monitoring and Control

Centralized Management: Operators can monitor material flow, system performance, and maintenance schedules from a single interface.

Error Detection: Sensors and alarms provide immediate notifications of blockages, shortages, or system malfunctions, preventing costly downtime.

7. Compliance with Industry Standards

Improved Hygiene: Closed systems ensure raw materials are free from contamination, meeting stringent production standards.

Eco-Friendly Operations: Reduced material waste and energy-efficient components contribute to sustainable manufacturing practices.

8. Enhanced Workshop Safety

Reduced Manual Handling: Automating material movement reduces the risk of injuries related to lifting and transporting heavy loads.

Fire Prevention: Properly dried materials lower the risk of hazards associated with moisture-induced issues.

Why Centralized Feeding Systems Are Ideal for New Workshops:

Establishing a centralized system during the setup phase minimizes future disruptions and retrofitting costs.

It creates a modern, streamlined foundation for high-efficiency operations and scalability.