Solutions

Guangdong Zoneke Technology Co,Ltd founded in 2014 and located in Hengli Town,Dongguan City, Guangdong province of China.

01

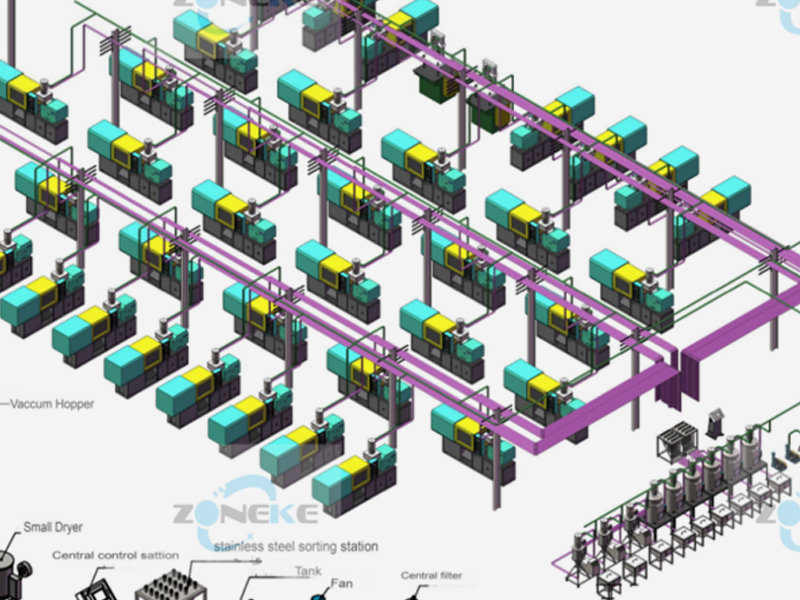

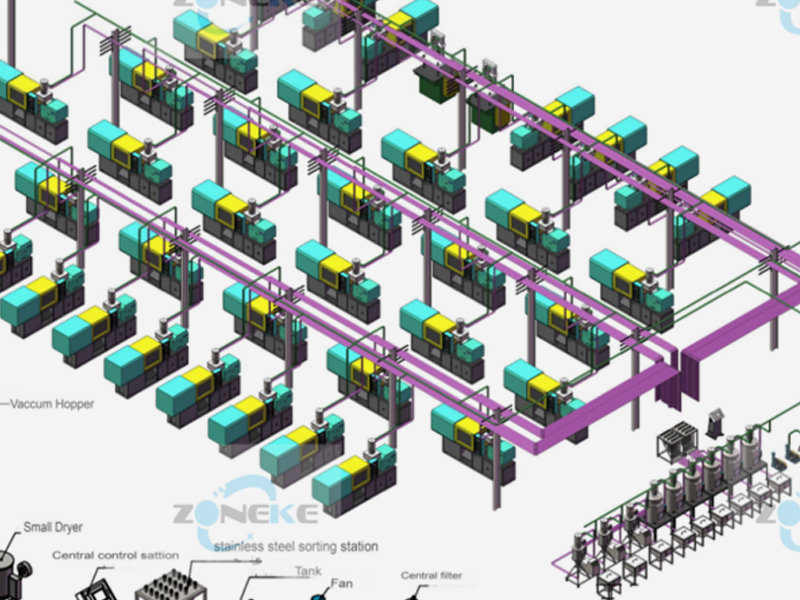

Central Material Handling System

02

PET Preform

System

03

Medical & Optical

Systems

04

Extrusion Blow

Molding

05

Central Cooling

System

Welcome to Zoneke

Zoneke is an intelligent manufacturing high-tech enterprise and integrating R&D, production, sales and service.

The injection molding division

Full-servo manipulators, dehumidifying and dryers,

mold temperature controllers, chillers, masterbatch machines, crushers and other injection molding machine peripheral equipment.

The Intelligent Manufacturing

Robot Automation Division

Patent Certificate

R&D Personnel

Production line

Blogs

-

Matching a robot arm to an injection molding machine involves several key steps to ensure compatibility, efficiency, and safety. Here's a guide to the process:1. Determine the Application and FunctionalityPick-and-Place: If the robot arm is used to handle parts (inserting or removing), assess the ro

Matching a robot arm to an injection molding machine involves several key steps to ensure compatibility, efficiency, and safety. Here's a guide to the process:1. Determine the Application and FunctionalityPick-and-Place: If the robot arm is used to handle parts (inserting or removing), assess the ro -

Implementing a Centralized Feeding System in a new plastic injection workshop provides numerous advantages that streamline operations, enhance productivity, and ensure long-term cost efficiency. Here are the key benefits:1. Improved Operational EfficiencyAutomated Material Supply: Centralized feedin

Implementing a Centralized Feeding System in a new plastic injection workshop provides numerous advantages that streamline operations, enhance productivity, and ensure long-term cost efficiency. Here are the key benefits:1. Improved Operational EfficiencyAutomated Material Supply: Centralized feedin

Cooperation Partners