-

Mold temperature control plays a critical role in the injection molding process by directly influencing the quality, efficiency, and overall success of the molded parts. Temperature control of the mold is essential for achieving optimal results in terms of product consistency, cycle time, and energy

Mold temperature control plays a critical role in the injection molding process by directly influencing the quality, efficiency, and overall success of the molded parts. Temperature control of the mold is essential for achieving optimal results in terms of product consistency, cycle time, and energy -

Matching a robot arm to an injection molding machine involves several key steps to ensure compatibility, efficiency, and safety. Here's a guide to the process:1. Determine the Application and FunctionalityPick-and-Place: If the robot arm is used to handle parts (inserting or removing), assess the ro

Matching a robot arm to an injection molding machine involves several key steps to ensure compatibility, efficiency, and safety. Here's a guide to the process:1. Determine the Application and FunctionalityPick-and-Place: If the robot arm is used to handle parts (inserting or removing), assess the ro -

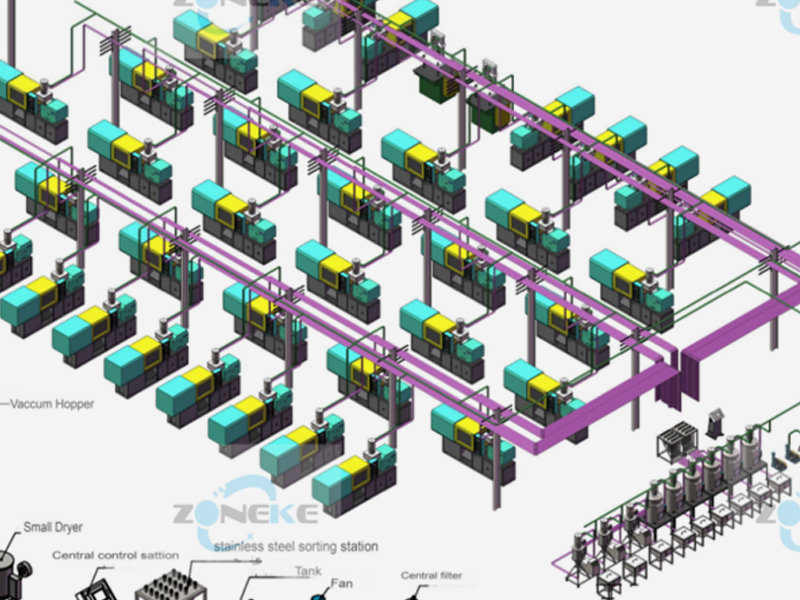

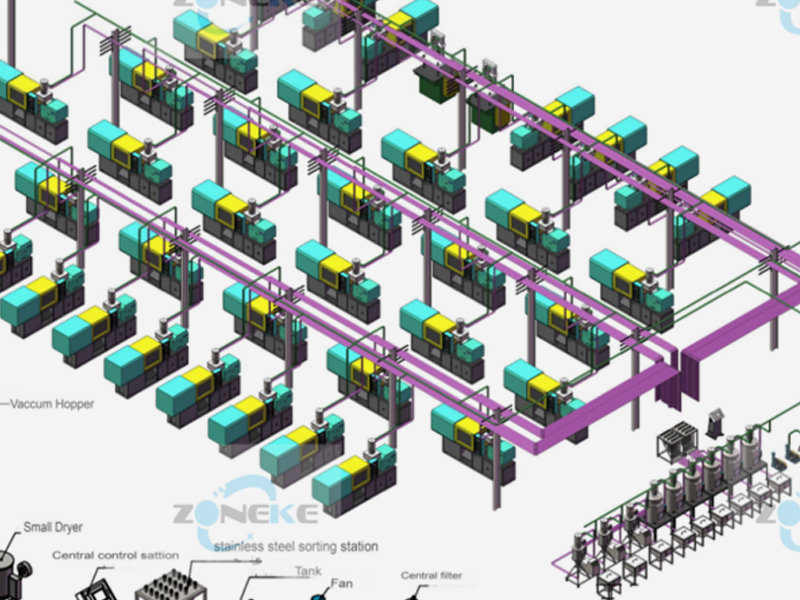

Implementing a Centralized Feeding System in a new plastic injection workshop provides numerous advantages that streamline operations, enhance productivity, and ensure long-term cost efficiency. Here are the key benefits:1. Improved Operational EfficiencyAutomated Material Supply: Centralized feedin

Implementing a Centralized Feeding System in a new plastic injection workshop provides numerous advantages that streamline operations, enhance productivity, and ensure long-term cost efficiency. Here are the key benefits:1. Improved Operational EfficiencyAutomated Material Supply: Centralized feedin