High Efficiency and Precision

Companies typically offer advanced technology and equipment that can achieve efficient cutting operations, ensuring product accuracy and consistency. This is especially important in industries that require high-precision processing, such as aerospace, automotive, and construction.

Professional Technical Support

These companies usually have experienced technical teams that can provide comprehensive technical support and after-sales services, helping customers resolve issues encountered during use, ensuring the normal operation and maintenance of the equipment.

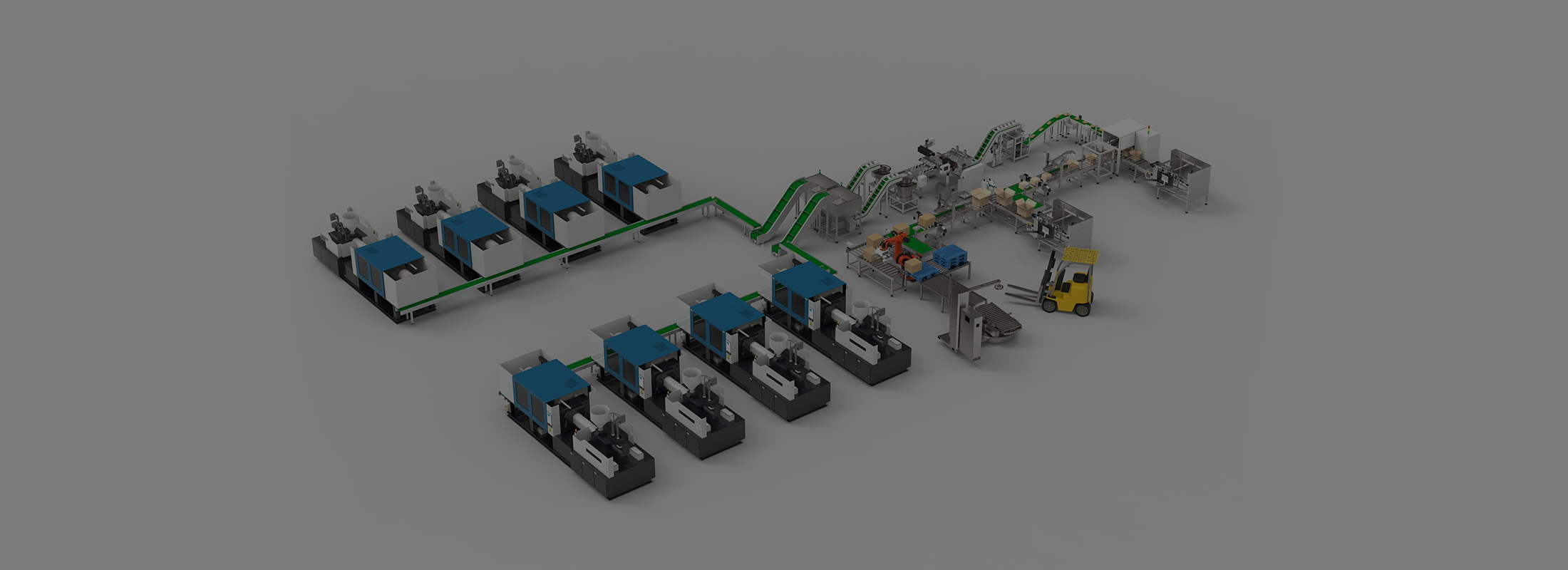

Customized Solutions

Large cutting machine companies can provide customized solutions based on the specific needs of customers, meeting different material and processing requirements. This flexibility allows customers to better adapt to market changes and improve production efficiency.