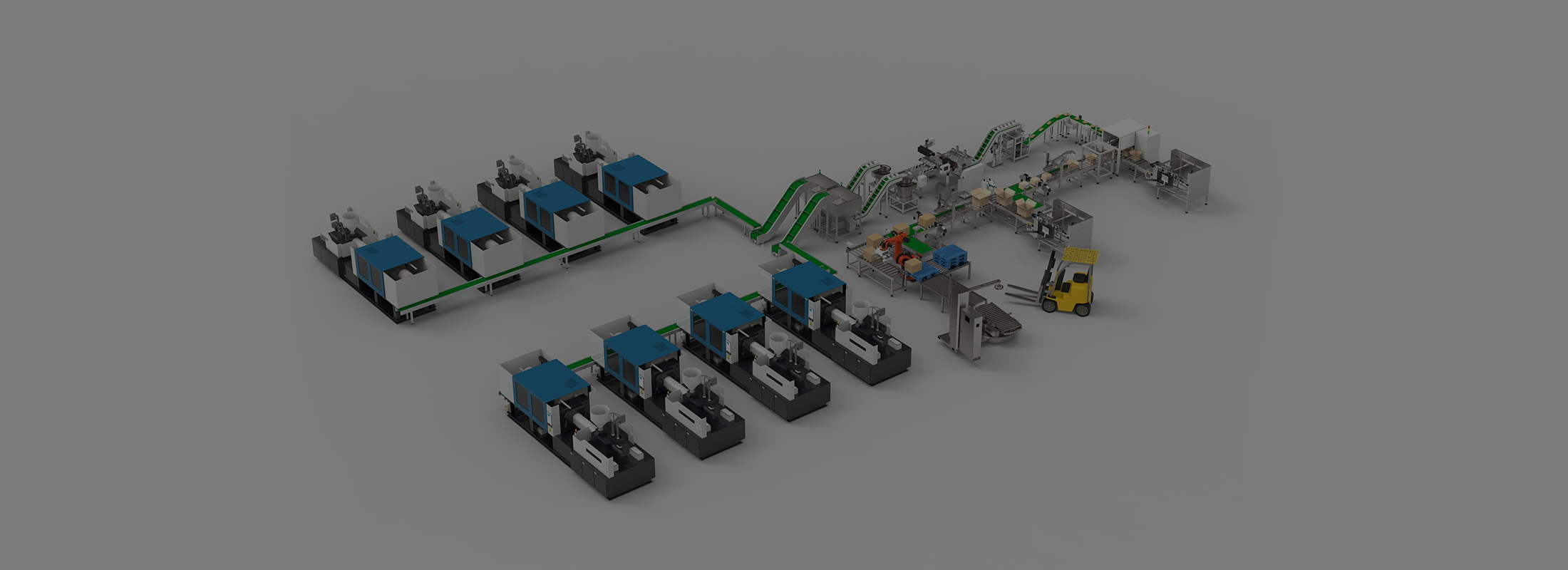

A central feeding system is an automated raw material supply device, mainly consisting of feeding equipment, conveying systems, and control systems. It achieves accurate supply of various raw materials through raw material silos, pipeline conveying systems, etc., ensuring stable raw material supply for production lines, improving production efficiency, and reducing labor costs and operational risks. This system is widely used in the plastic molding industry, capable of simultaneously realizing functions such as raw material drying, conveying, and proportioning, and has become one of the important devices in industrial production.

1. Improve Production Efficiency

The central material supply system utilizes automated control technology to achieve precise monitoring and control of the material supply process, enabling 24-hour uninterrupted supply and significantly improving production efficiency. The system can quickly adjust the material supply to meet changing production demands, enhancing the flexibility and responsiveness of the production line.

2. Reduce Labor Costs

The operation of the system is relatively simple, requiring only a few personnel to manage the entire material supply process, reducing reliance on manual labor and thereby lowering labor costs and work intensity.

3. Enhance Product Quality

The central material supply system enables precise measurement and uniform mixing, minimizing defects such as color variations and insufficient strength caused by raw material issues, thereby improving product yield and batch consistency.

4. Save Space and Equipment Investment

By centralizing the material supply, the system reduces the need for raw material conveyors and auxiliary equipment next to injection molding machines, increasing space utilization. Additionally, the centralized design reduces the number of equipment units, thereby lowering energy consumption and maintenance costs.

5. Improve Safety and Environmental Protection

The central material supply system uses enclosed transportation and centralized dust collection, maintaining a clean production environment that meets cleanroom standards, reducing noise and dust pollution during production, improving air quality, and promoting employee health.

6. Modern Factory Image

The application of the central material supply system makes the production workshop more organized and tidy, reduces clutter from raw material bags and individual machines, and establishes the image of a modern, well-managed factory.